Introduction

Ikram Rice Mills is a leading producer and exporter of premium Basmati rice from Pakistan. With over 20 years of excellence, the company combines traditional rice milling methods with advanced technology to deliver high-quality rice. Their commitment to quality ensures that each grain is fresh, flavorful, and nutritious. Serving global markets, Ikram Rice Mills offers a variety of rice products, including Basmati and non-Basmati varieties, with a focus on purity and customer satisfaction.

Our Plant

Ikram Rice Mills operates on a 15-acre premise with a husking capacity of 10 metric tons per Hour (7200 metric tons monthly). The plant boasts a parboiling capacity of 500 metric tons per day and a drying capacity of 15000 Metric Tons Monthly . With a storage capacity of 800,000 bags (65kg each), the facility is self-sufficient in power generation, featuring a 1 MW solar power plant and a water treatment system. The company also offers private labeling and customized packaging options for clients.

Parboiling Capacity

Our parboiling capacity stands at 500 metric tons per day, translating to an impressive 15,000 metric tons monthly. This advanced process ensures superior grain quality, mitigating unwanted odors and preserving the natural fragrance and aroma of the rice. The integrated water treatment plant supports this process by providing soft water, ensuring hygienic and efficient operations while maintaining the highest standards of quality.

Drying Plant

At Ikram Rice Mills, we prioritize effective seed drying to maintain grain quality and extend storage viability. Delays or improper drying can lead to reduced seed quality, pest infestations, and fungal growth due to moisture-induced “hot spots.” Our advanced drying techniques reduce moisture content to safe levels while preserving the seed’s natural viability and quality. By ensuring optimal conditions, we prevent deterioration and maintain the integrity of the grain, supporting long-term storage and superior product standards.

Rice Milling

At Ikram Rice Mills, our husking capacity is 10 metric tons per hour, equating to 7200 metric tons monthly. Utilizing cutting-edge technology, including state-of-the-art equipment, we ensure precision and efficiency in meeting the highest standards for milled rice. The facility features advanced Pre-cleaners, De-stoners, Precision-sizers, Graders, Paddy separators, De-huskers, and Magnets. Fully computerized inflow and outflow systems with sensors ensure seamless operations. Our environment-friendly premises are designed to prevent contamination, maintaining the integrity and quality of the rice.

To achieve this, we incorporated Satake’s and Buhler advance technology into our rice processing operations.

Godowns Storage

At Ikram Rice Mills, we have made significant investments in storage infrastructure, including silo storage and additional warehousing facilities. Our storage capacity is an impressive 800,000 bags, each weighing 65 kg. These facilities are equipped with separate fumigation chambers to ensure a cleaner, insect-free environment, maintaining the quality and safety of the rice.

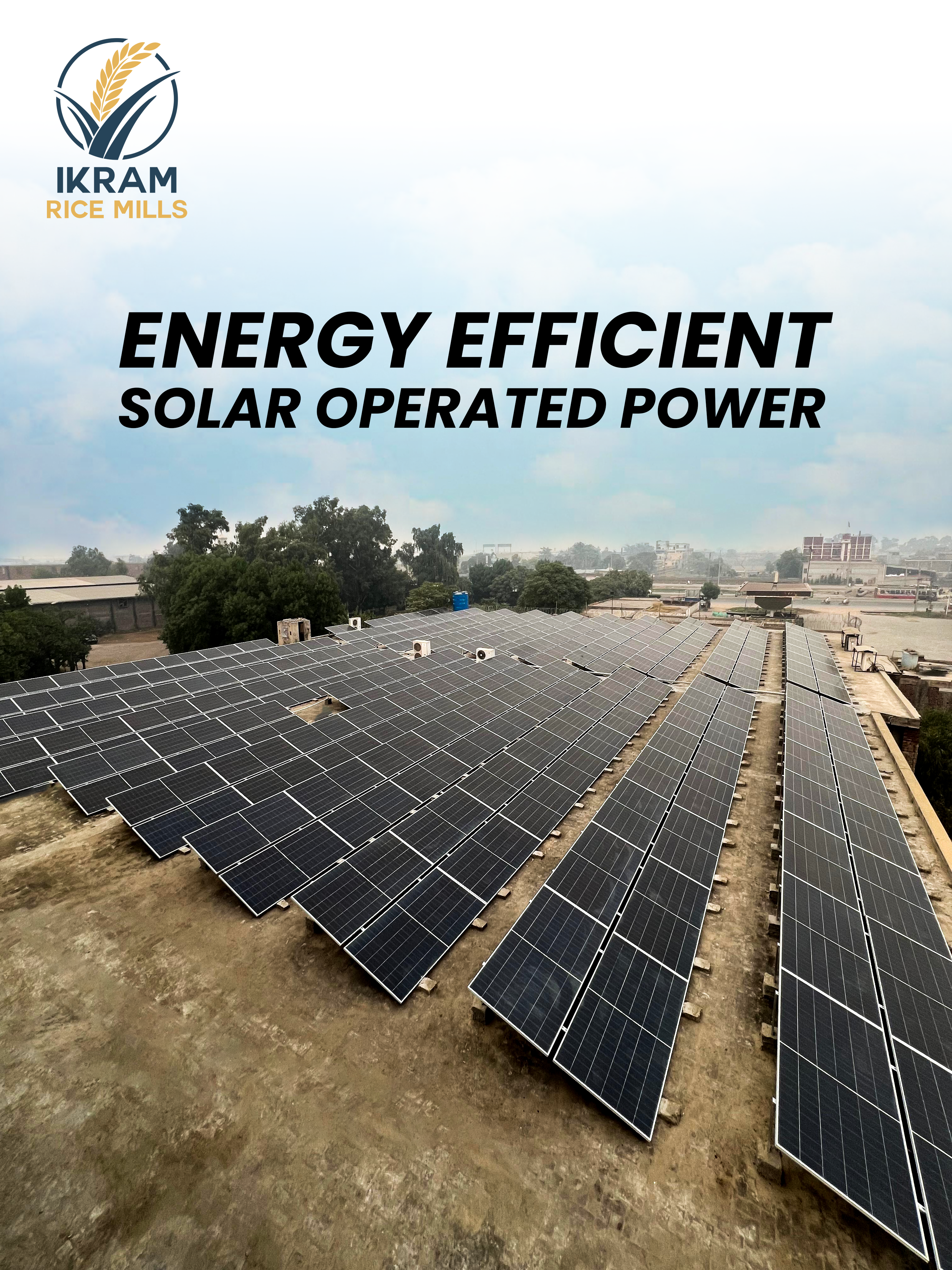

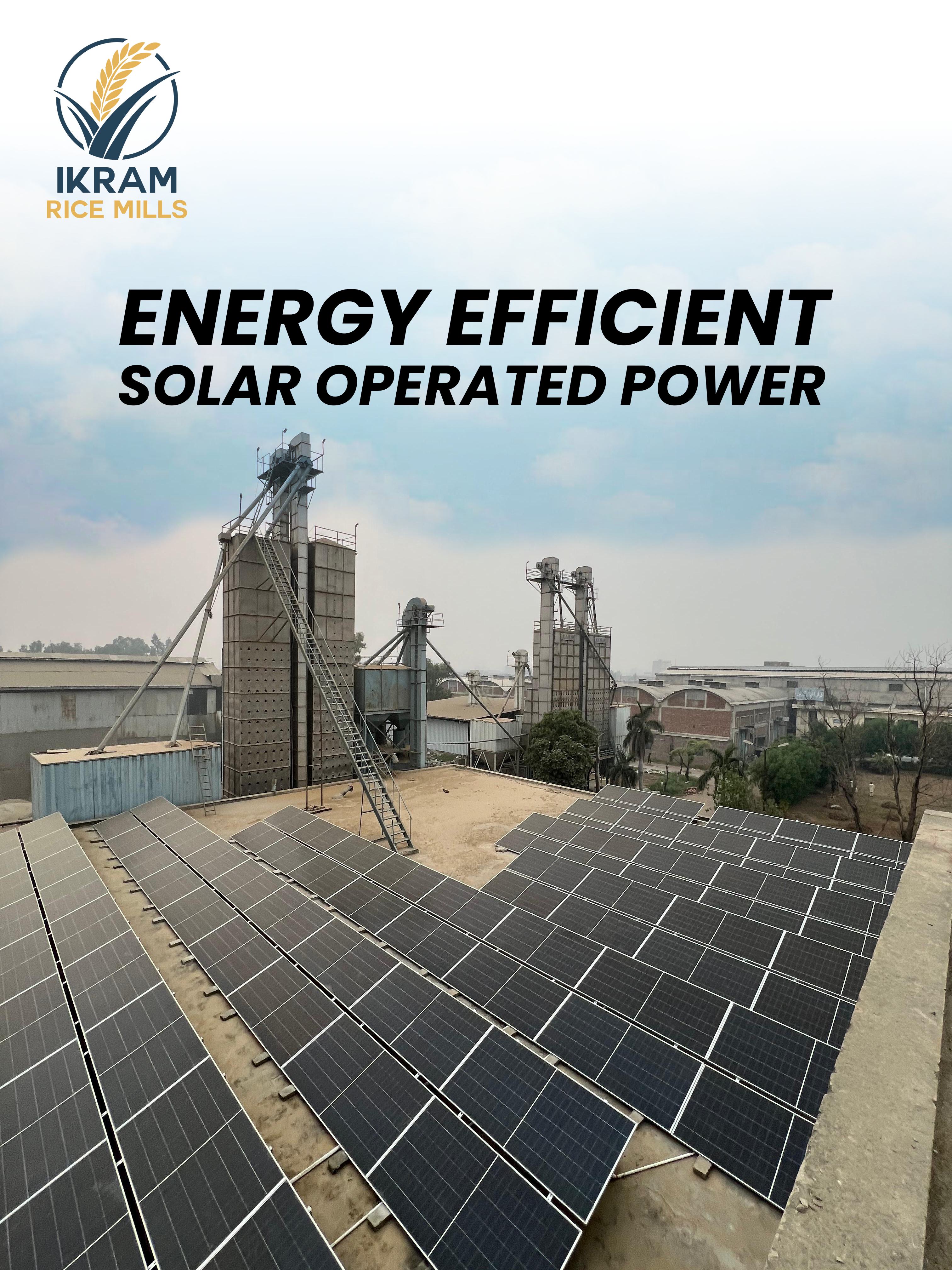

Sustainable Energy

Ikram Rice Mills harnesses the power of a 1 Megawatt Solar Power Plant, reducing environmental impact and ensuring reliable, green energy for its operations. This renewable energy initiative underscores the company’s commitment to sustainability and energy efficiency.

24/7 Power Backup

Ikram Rice Mills is equipped with a 24/7 power backup system, ensuring an uninterrupted supply of electricity even during power outages. This system automatically activates in case of power disruptions, allowing essential equipment and operations to continue without delay. This guarantees that all consignment and delivery schedules are met on time, maintaining the efficiency and reliability of our operations.

Rice Processing

Ikram Rice Mills operates with a processing capacity of 7 Metric Tons per hour (6000 Metric Tons monthly). Its fully mechanized plants utilize advanced technology for cleaning, de-stoning, polishing, sorting, and grading, all adhering to international standards. Strict process controls ensure the preservation of the rice’s aroma, fragrance, and quality, delivering consistently premium grains. To achieve this, we have incorporated Satake’s and Buhler’s advanced technology into our rice processing operations, ensuring efficiency and superior output at every stage.Cleaning

At Ikram Rice Mills, we prioritize quality with a cutting-edge processing system that includes advanced winnowers, pre-cleaners, and cleaner-separators to eliminate impurities and prepare grains for drying. These machines, equipped with hoppers, fans, and sieves, ensure optimal cleaning and sifting for superior rice quality. To achieve this, we have incorporated Satake’s and Buhler’s advanced technology into our operations, enhancing efficiency and maintaining our commitment to delivering premium rice products.

Color Sorting

At Ikram Rice Mills, we are committed to delivering the highest quality rice to our customers. By integrating Satake’s top-tier rice colour sorting machines, we can accurately identify and remove any discolored, broken, or damaged rice, leaving only the highest quality grains. To achieve this, we incorporate Satake’s advanced rice colour sorting technology into our rice processing operations, ensuring that every grain of rice meets stringent quality standards. Our state-of-the-art sorting machines utilize precision CCD cameras and high-resolution sensors to detect and remove unwanted contaminants, damaged grains, and other imperfections. This allows us to provide rice that is not only visually appealing but also free from foreign materials, ensuring a premium product for our consumers.Packaging

At Ikram Rice Mills, we use automated packaging systems to ensure efficient and accurate packaging of rice. Our systems fill bags to precise weights and are equipped with sealing mechanisms to guarantee product integrity. The packaging process is followed by thorough inspection to ensure consistency and quality. Our bags are designed to maintain the freshness and quality of the rice, with clear labeling that reflects the product’s superior quality.